Team members

Kyaw Htet Paing (ASD), Paris Lau Sherneese (ASD), Brandon Joseph Lawrence (EPD), Lee Jie Hong (EPD), Adler Teo (ASD), Song Li Ying (ASD), Chua Wei Han (EPD)

Instructors:

Thomas Schroepfer, Yang Hui Ying

Writing Instructors:

Teaching Assistant:

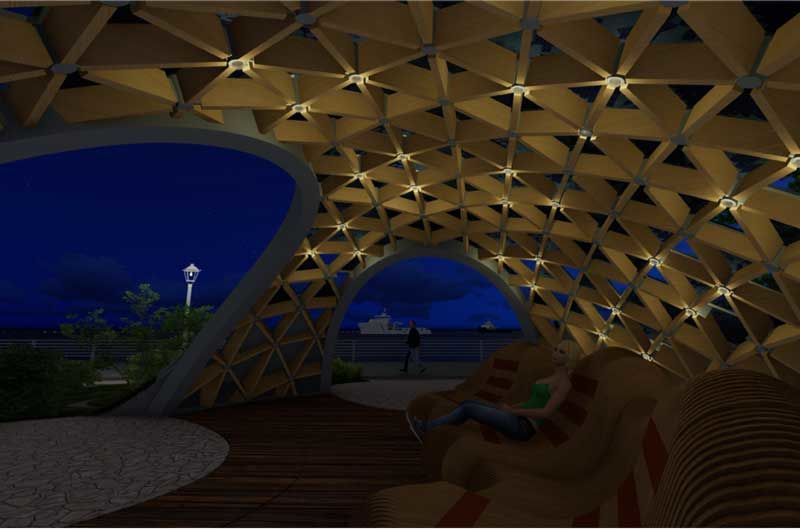

A modern pavilion that seemingly “emerges” from underground and integrates into the foliage ground in Labrador Park. The pavilion design integrates passive and active cooling features to provide a cooler, more comfortable spatial experience for the park goers.

Project Summary

Existing pavilions at coastal parks in Singapore depend solely on passive cooling measures like wind, trees, etc. to provide thermal comfort to park users in the form of shade and evapotranspiration. However with increasingly warmer weather, there are opportunities for novel strategies to be developed to attract coastal park visitors even during hotter times of the day.

Project "So Cool" explores the engineering and architectural design potentials of utilizing on-site forces, conditions and energies to create a literally “cool” experience within a tropical park setting in Singapore.

The solution builds upon existing passive cooling concepts, enhancing them via new architectural designs while also integrating a solar-powered active cooling system. The active (contact) cooling system embeds ‘cool touch points’ in the pavilion’s seats for park goers to keep themselves cool while enjoying the park environment.

Moreover, by incorporating a ‘peeling effect’ of the outer shell of the pavilion from the ground, it is able to integrate seamlessly with the surrounding greenery in the park. This elevates the proposed solution to a level above existing pavilion designs not only in areas of thermal comfort and functionality, but in structural aesthetics as well, creating an overall improved park experience.

Concept Diagram

Triangulated grid shell structure was used in this project as it was necessary to hold the dead load, solar panels, and green façade (plant boxes) that were going to be mounted on the roof of the pavilion structure. Triangulated grid shell is a structurally efficient way to span large distances with the minimal usage of columns. Known as thin shells, they are shallower for the same span than trusses or space frames, hence they are suitable for creating dome-like structures. The triangulated grid-shell structure was therefore, chosen to integrate into the structure.

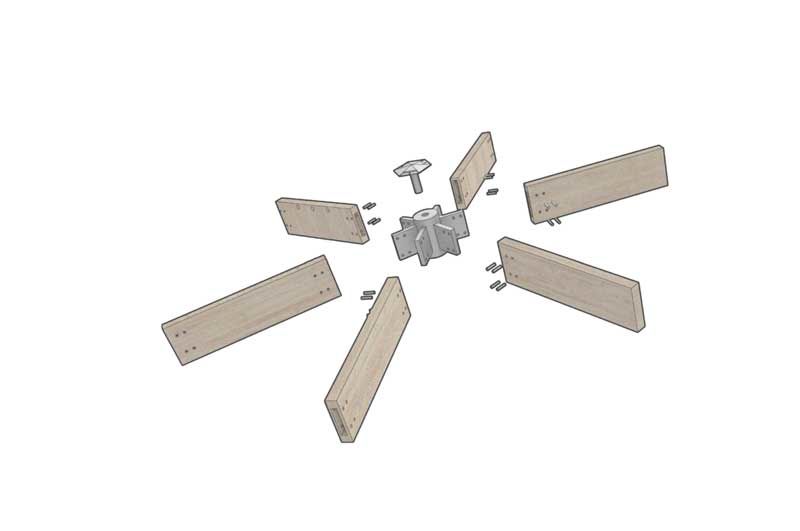

Joints

The joints in the triangular grid structure are nodes that receive six elements (6 wooden pieces). Each connection is at a slightly different angle, easing fabrication while keeping the scale of the triangles visually consistent. Thus, the flow of the surface design appears smooth and natural, and the transfer of forces is unimpeded.

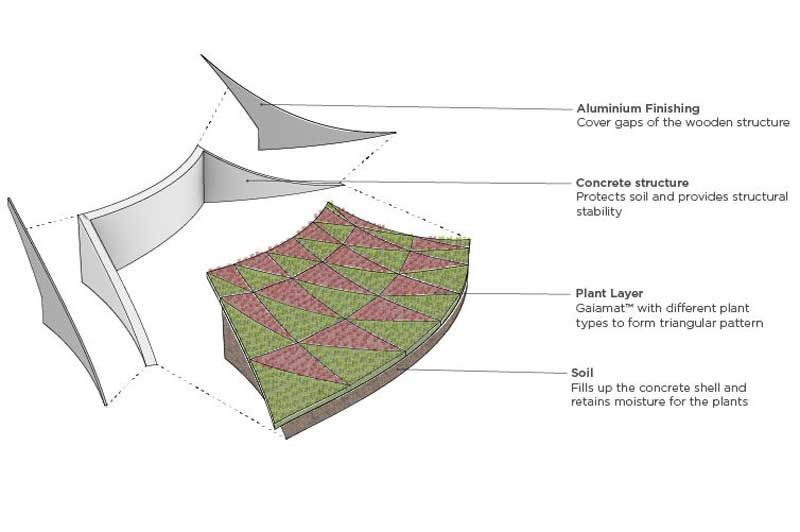

The green blanket is a planting strategy that peels off from the ground to follow the curvature of the pavillion. It evapo-transpires to keep the pavilion cool.

Green Mat

From the ground, the peeling effect starts from the green mat which utilises the Gaiamat™ - a soiless system that is only 7cm thin and easy to maintain. The triangular pattern will be expressed through two different plant species. It will be structurally supported by concrete and filled up with soil to retain excessive moisture for the plants. Aluminium cladding will cover up the holes at the sides.

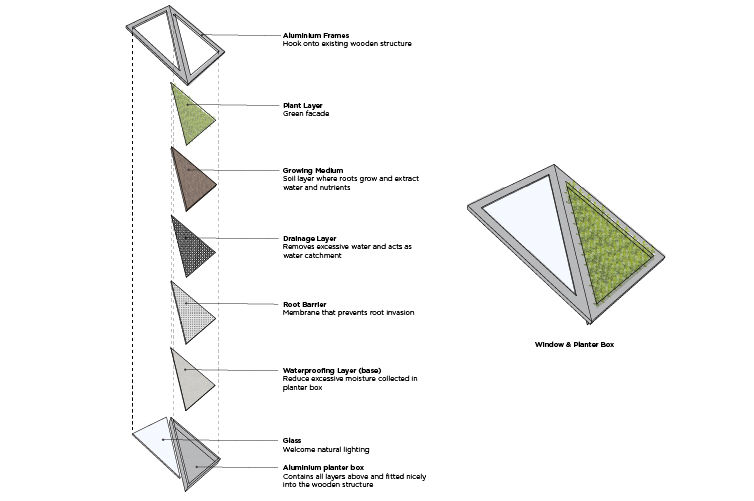

Planter Box

Where the concrete shell reaches its height limit and is unable to support the green blanket, planter boxes are used. Being customised, it will be fitted nicely into the wooden structure and held in place by aluminium frames.

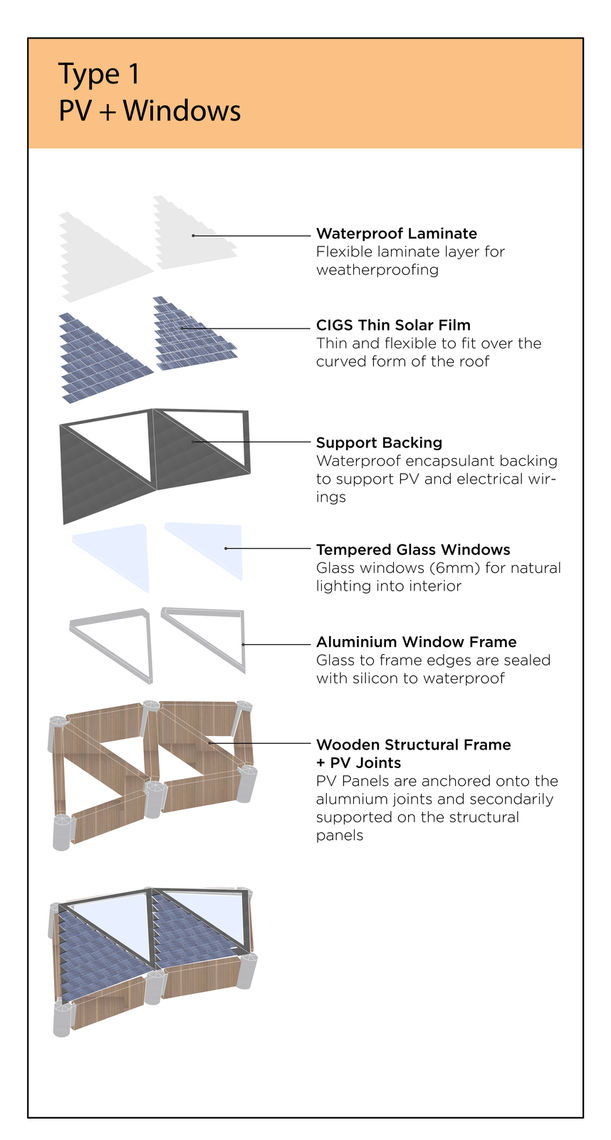

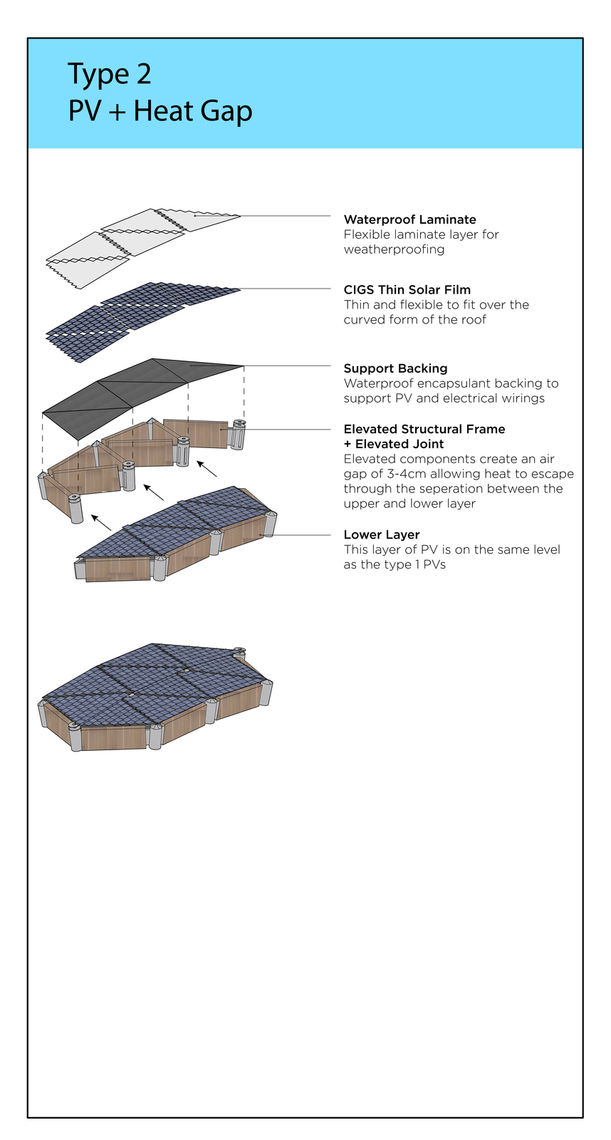

Integrated Roof Design

Solar cells is our sustainable roof strategy to provide renewable energy to our active cooling system while ensuring adequate shading and comfort to the interior of the pavilion.

We designed the PV system to cope with the physical needs of the pavilion which includes: Energy generation, natural illumination, ventilation and dissipation of heat.

We are using CIGS solar thin film for its unique flexibility and heat loss properties and its high energy conversion at ~14%. PV cells will be supported on the wooden structural panels of the pavilion main frame and anchored at nodal points with aluminium joints.

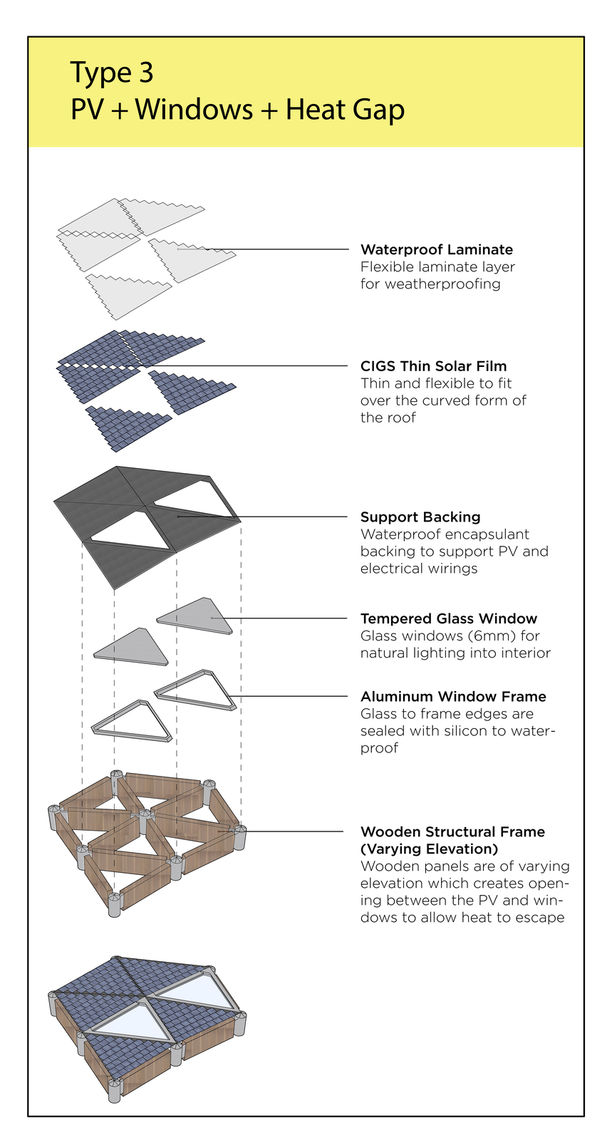

1. SANDBOX

SANDBOX behind the seat allows family with children to visit pavilion without worries. The children can play with the sand while the parents relax in the pavilion.

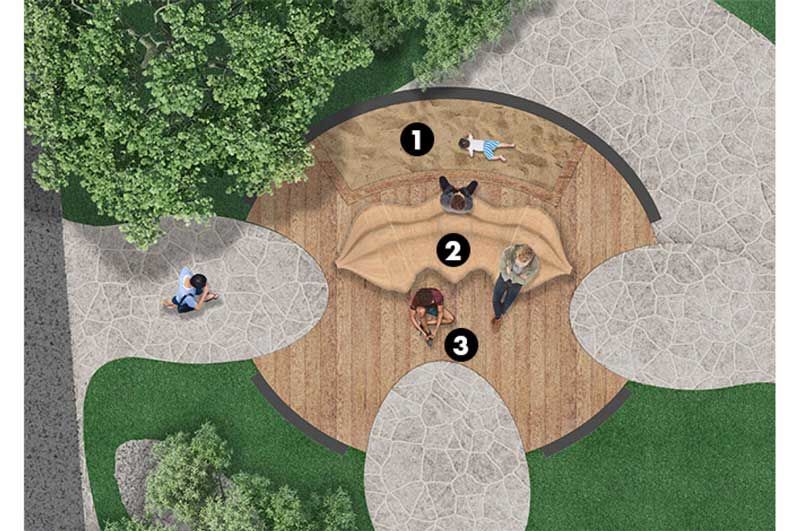

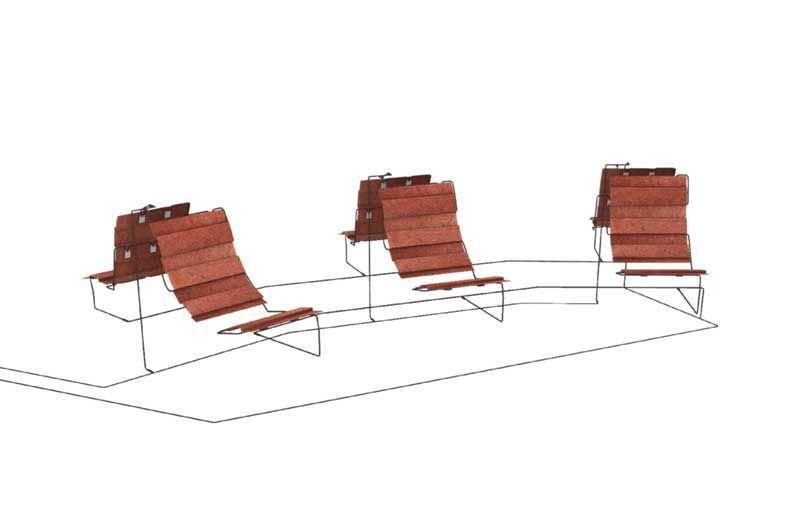

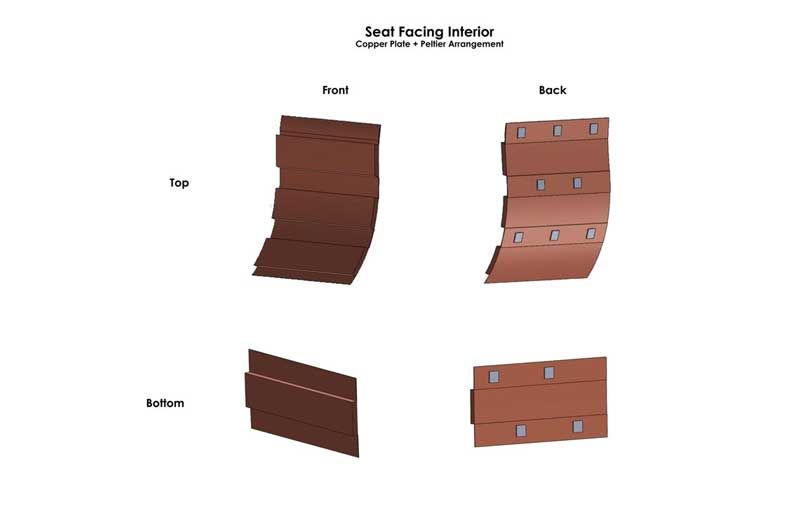

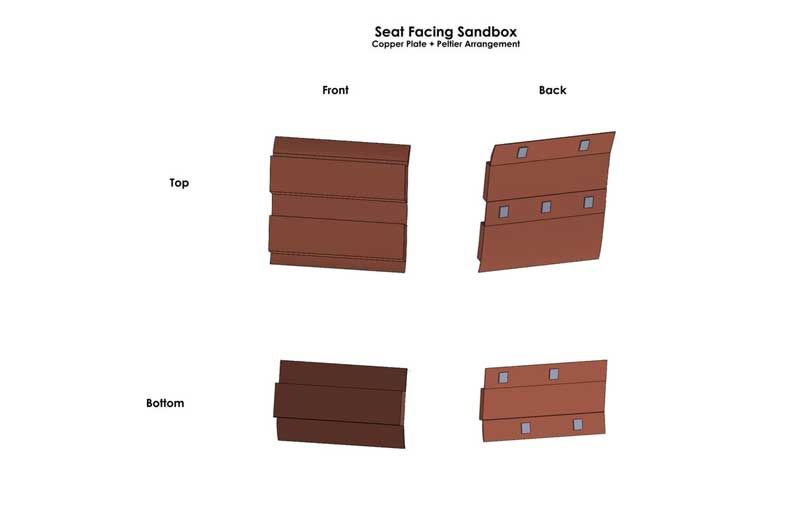

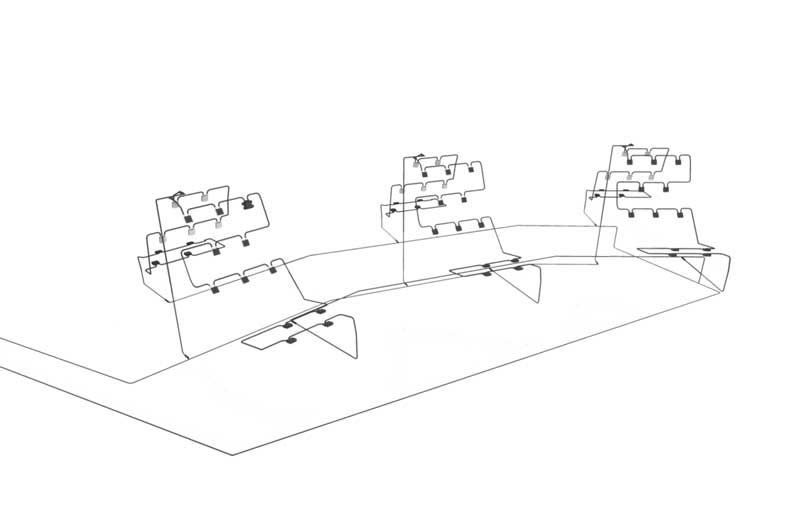

2. Contact Cooling Seat: SEAWAVE

Double-sided seat provides two comfort levels for seating: The side facing the SANDBOX is an upright seat for parents to supervise their children at the SANDBOX; the side facing the entrance allows users to partially lie down comfortably to enjoy contact cooling in the hot weather.

3. Floor Seating

Families can have a small picnic by laying mat and sit on the wooden floor decking to socialise and enjoy their time.

Contact Cooling System in Seat Feature

The contact cooling within the seat works on the principle of the Peltier Effect through the operation of Thermoelectric Cooler Chips (Peltier Chips). When an electric current flows through the junction of 2 conductors in a chip, heat is removed from one junction and transferred to another junction, thereby creating a cooling effect. This cooling effect is enhanced in the seat through the use of copper plates with excellent thermal conductivity that are in thermal contact with the array of Peltier Chips.

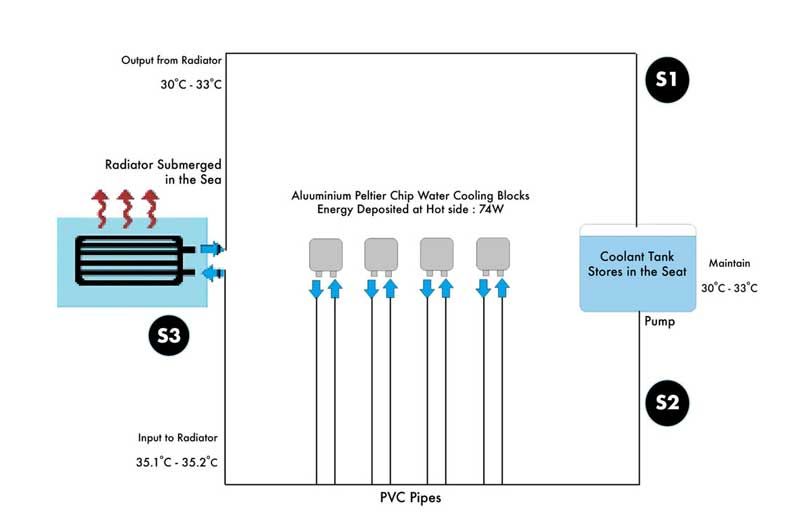

Water Piping System

For the contact cooling system, due to the Peltier Effect, heat will constantly be transferred to the hot side of the chips. Thus to prevent overheating at the hot sides of the chips, a water piping system has been implemented within the seat feature.

In this system, water is pumped using a centrifugal pump (S1) from a water tank underground. This water then travels through underground pipes before reaching the water block array (S2) within the seat feature where each water block is in thermal contact with the hot side of one Peltier Chip. Via forced convection of fluid (water) flow, cooling takes place at the hot side of the chips. Heat is transferred to the water flowing through the water block array and this heated-up water then flows through underground piping from the seat feature to a radiator submerged in the sea (S3).

Once again, via forced convection of the sea water flowing around the copper pipes of the radiator, the heated-up water is cooled back down to approximately the room temperature range before flowing back to the underground storage water tank to repeat the cycle.

Electrical Systems within the Pavilion

Solar Energy Harvesting System Circuit

This circuit involves the generation of electrical energy from an array of 141 solar panels which will be situated on the roof of the pavilion. The electrical energy generated will then be stored in a 24V Lithium Ion Battery and a regulator connected to this battery will ensure that the current and voltage values are within desired ranges before it is supplied to the other electrical components within the pavilion such as the lighting, water pumps, water valves and the Peltier Chip contact cooling array.

Active Cooling System Circuit

The active cooling electrical circuit consists of relay components connected to the centrifugal pump in the water tank as well as each row of Peltier Chips on each of the copper plates behind the 6 seats. The electrical energy generated by the solar panels of the pavilion will be supplied to the components of the active cooling system circuit when required and this will be controlled by a system of sensors which make up a controller system.

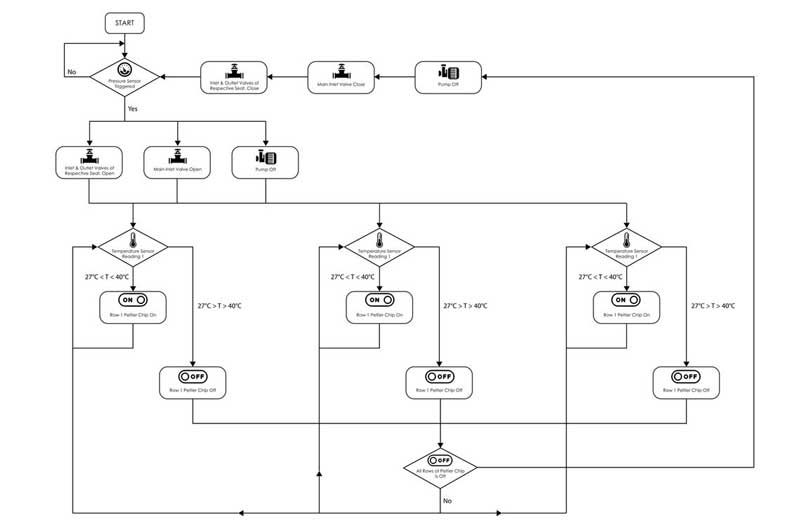

Controller System Circuit

The Controller System consists of a system of sensors connected to solenoid valves, a centrifugal pump and the Peltier Chip array to maintain the temperature of the contact cooling strips on the copper plates at a temperature of 27°C when a user is sitting on the seat. This will help to ensure that optimal thermal comfort is provided to users of the seat feature. The logic flow diagram on the left (for a single seat), demonstrates how the overall controller system works to provide this optimal thermal comfort.

In collaboration with:

Kyaw Htet Paing

Architecture and Sustainable Design

Kyaw Htet Paing

Architecture and Sustainable Design

Paris Lau Sherneese

Architecture and Sustainable Design

Paris Lau Sherneese

Architecture and Sustainable Design

Brandon Joseph Lawrence

Engineering Product Development

Brandon Joseph Lawrence

Engineering Product Development

Lee Jie Hong

Engineering Product Development

Lee Jie Hong

Engineering Product Development

Adler Teo

Architecture and Sustainable Design

Adler Teo

Architecture and Sustainable Design

Song Li Ying

Architecture and Sustainable Design

Song Li Ying

Architecture and Sustainable Design

Chua Wei Han

Engineering Product Development

Chua Wei Han

Engineering Product Development

Kyaw Htet Paing

Architecture and Sustainable Design

Paris Lau Sherneese

Architecture and Sustainable Design

Brandon Joseph Lawrence

Engineering Product Development

Lee Jie Hong

Engineering Product Development

Adler Teo

Architecture and Sustainable Design

Song Li Ying

Architecture and Sustainable Design

Chua Wei Han

Engineering Product Development

© 2020 SUTD